Dropshippingĭropshipping is an inventory management technique that doesn’t require the seller to keep inventory items in stock. While JIT can reduce inventory costs, it can also result in stockouts and isn’t suitable for all businesses. To do so, you’ll need to closely track inventory levels and work closely with suppliers.

Just-in-time (JIT) inventory is a management method that reduces the amount of inventory you have on hand by only ordering and delivering products at the exact time you need them. PAR levels are based on an item’s average daily demand, lead time and amount of safety stock. Implementing the PAR levels inventory management technique can therefore avoid both stockouts and overstocking and is best for businesses with perishable items, such as restaurants. However, inventory shouldn’t exceed the maximum level. When inventory quantity reaches the minimum level, a new order should be placed. Periodic automatic replenishment (PAR) levels track the minimum and maximum levels of inventory maintained for an inventory item. Reorder points are an essential part of inventory management and help you avoid stockouts. Reorder points are specific to individual inventory items and are based on that item’s average daily usage, order lead time and the amount of safety stock you have on hand. Reorder points represent the inventory levels at which new orders should be placed. Safety stock is determined based on demand variability, delivery lead time, the cost of stockouts and the cost of holding inventory. Safety stock is important if you want to avoid stockouts. Safety stock represents the amount of extra inventory you keep on hand to cover unexpected demand or delays in future deliveries.

B Items: Items with medium importance to the business that account for 30% of the inventory items and roughly 15% of the inventory value.A Items: The most important items that account for 20% of the inventory items but up to 80% of the inventory value.When conducting an ABC analysis, divide your inventory into three categories: This is most helpful when a business needs to prioritize which items to order and store, allowing for more oversight on certain inventory items. ABC AnalysisĪBC analysis is an inventory management technique that ranks inventory items based on their importance to your business.

Regardless of the technique you choose, it’s important to note that demand forecasting will never be exact, which may lead to stockouts or overstocks. The right technique will depend on your unique business.

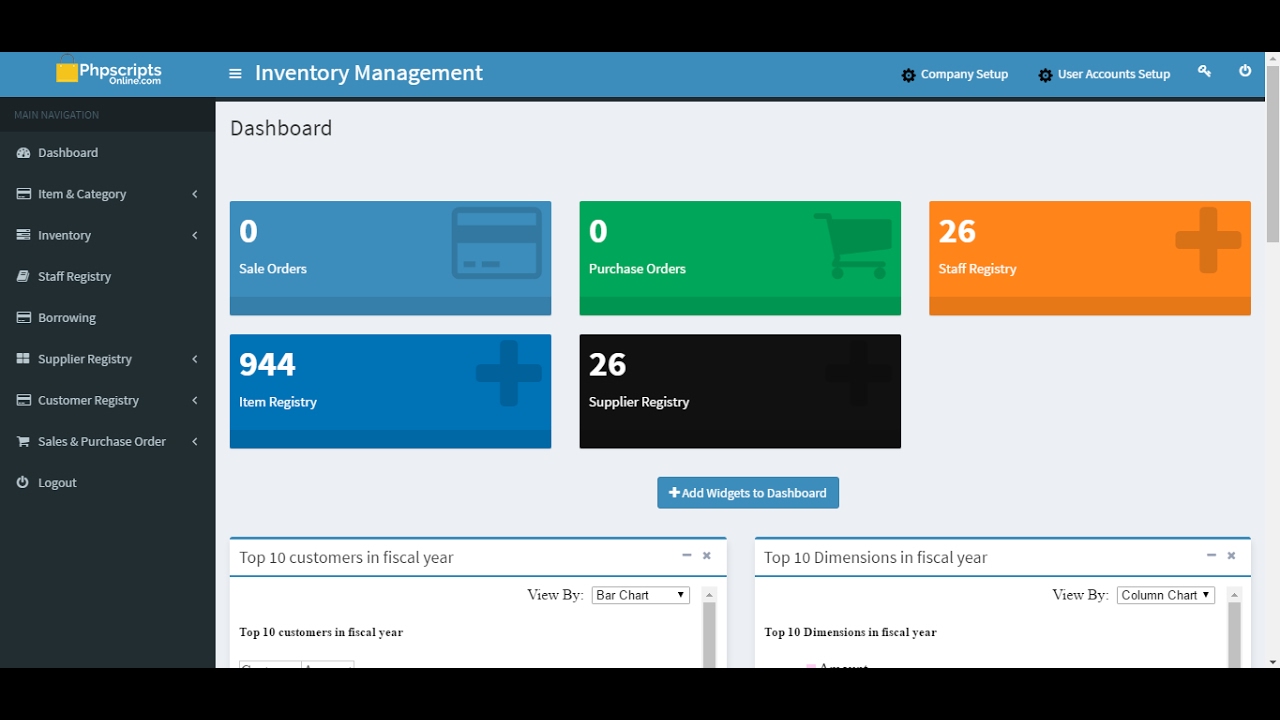

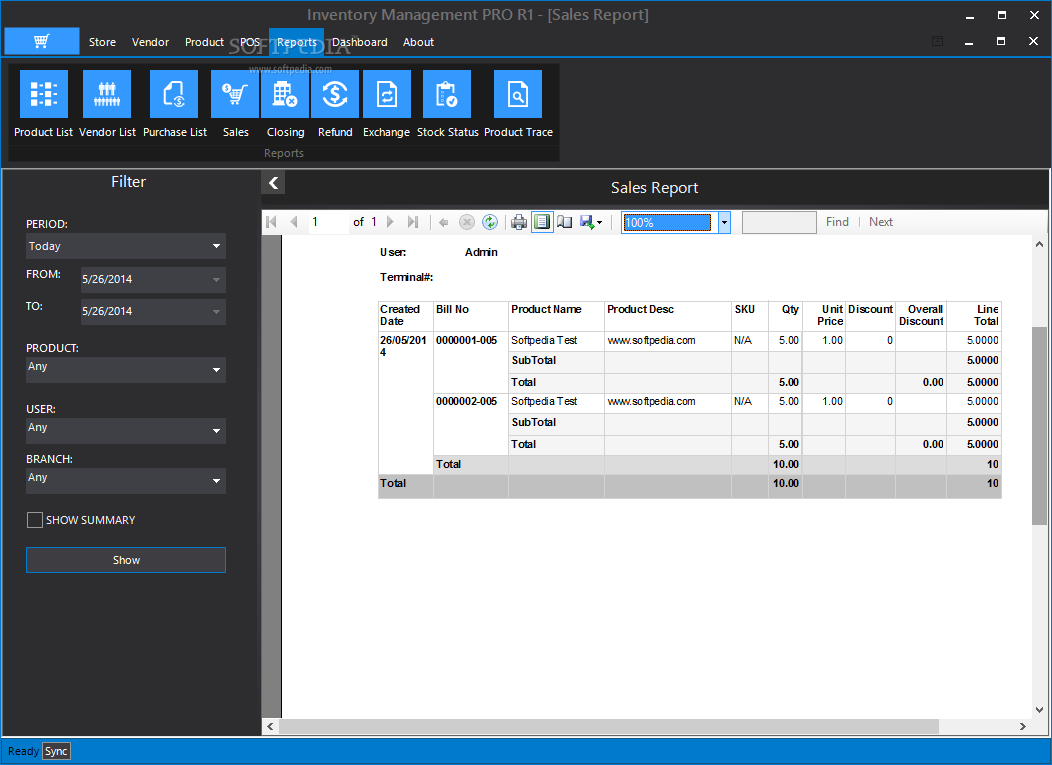

PERSONAL INVENTORY MANAGEMENT WEBSITE SERIES

Some of the top ways to forecast your demand include a moving average, exponential smoothing, time series analysis and judgmental forecasting. If you forecast demand well, you ensure that you’ll have the right amount of inventory on hand to meet customer demand. Demand Forecastingĭemand forecasting is the act of accurately predicting future demand for your products and is something every business should do. Here are the top 17 inventory management techniques and why they’re important: 1. When choosing the best techniques for you, make sure to consider the type of product you sell, the size of your business, your overall budget and the level of accuracy needed to run an effective supply chain. There are many inventory management techniques, each with its own benefits and drawbacks. With this in mind, let’s take a look at the top inventory management techniques to help you manage your inventory more effectively. If you do it right, you’ll be able to increase sales, lower costs and better serve your customers. The benefits of inventory management are numerous. Improves Customer Service: Having the right inventory to meet customer demand results in happier customers with fewer frustrations.Effective inventory management reduces these costs by minimizing the inventory you hold. Reduces Cost: The longer you hold inventory, the more it costs due to holding costs, handling costs and costs resulting from obsolete or spoiled inventory.This helps you avoid supply shortages that can eat into revenue. Increases Revenue: Effective inventory management ensures that you have the right products on hand at all times, allowing you to meet customer demand.Specifically, inventory management is important due to the following reasons: On Katana's Website Why Is Inventory Management Important?Įffective inventory management is important because it can help increase revenue, reduce cost and improve customer service.

0 kommentar(er)

0 kommentar(er)